I spent a significant portion of my weekend working on the telecine project. The test films I ordered from ebay arrived Friday and I immediately popped one on the projector. Unfortunately, the take up reel/spool kept turning too quickly and pulling the film against the second (lower) sprocket. Having never used a projector before and knowing this projector was formerly in working condition, I assumed the problem was a user error. After triple checking everything, I decided the take up reel must be the wrong size… but then I checked ebay listings and the take up reels looked identical. I then pulled the service panel off the projector since I had it off earlier – perhaps I misplaced a gear? Nope! But I did find a spring loaded mechanism at the take up reel and after looking closely, I determined that the take up reel is supposed to slip except it wasn’t. I held the gear in place and forced the take up reel until it finally gave way. After that, it slipped much more easily and the projector began to operate correctly!

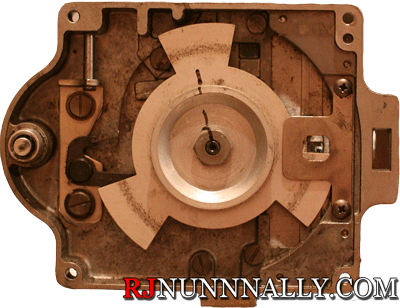

After a successful test of the projector, I then started disassembly. The film needs to be advanced frame by frame for the telecine so the motor either needs to be controlled directly or replaced entirely. Pictured above is the view of the projector with the motor and lamp housing removed entirely. The Bell and Howell Regent Design 122 Model L appears to be a great telecine platform because the assembly above rotates exactly once for every frame. Rather than control the original motor, I have decided to build a new motor assembly that will be controlled by a microcontroller. For the lamp, I have decided to reverse the projection and mount the camera where the old lamp used to be with an LED light source mounted where the current projection lens is in front.

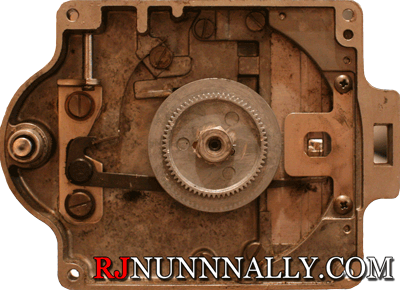

The new motor assembly is based on parts ripped from an old cassette deck. The dc motor is from the deck along with the gears needed to make everything work. The gears need machining to fit the projector, but otherwise look like a good fit. I have already done the necessary machining to mount one of the gears.

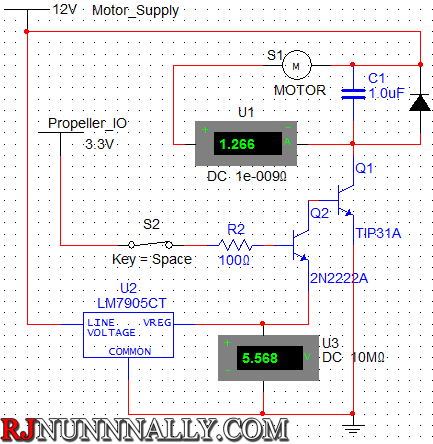

The microcontroller is not able to directly control a powerful DC motor, so a control circuit is needed. I first modeled the circuit in multisim, then breadboarded it for testing. The circuit above is not identical to the breadboarded circuit – I omitted the capacitor and the 2N2222A is directly driven from the 5v rail on a PC power supply; I threw the 7905 in because it’s already mounted to the spare perf board I have from a previous project.

The motor will need to carefully advance the film and cannot run too quickly. I drafted not particularly elegant PWM code on the propeller and ran a few tests. This will allow the motor to run at lower power levels so as not to over advance the film.

I think this was at 66% duty cycle, but I don’t recall exactly. Each square is 1 ms.

Next to come is the mounting of the DC motor and closed circuit control. Once completed, all that remains is to mount the light source and camera, then scan some film!